The automotive industry is undergoing a fundamental transformation driven by software-defined vehicles (SDVs), advanced driver assistance systems (ADAS), electrification, and centralized E/E architectures. As vehicle functions grow in complexity and data intensity, traditional in-vehicle communication protocols are being stretched beyond their original limits.

Controller Area Network (CAN) has been the backbone of automotive communication for decades. However, modern automotive requirements demand higher bandwidth, better scalability, and seamless coexistence with legacy systems. This evolution has led to CAN FD (Flexible Data Rate) and the emerging CAN XL (Extra Long) protocol.

This blog explores CAN FD and CAN XL controllers, their architectural features, and their role in current and future automotive applications.

Evolution of CAN in Automotive Systems

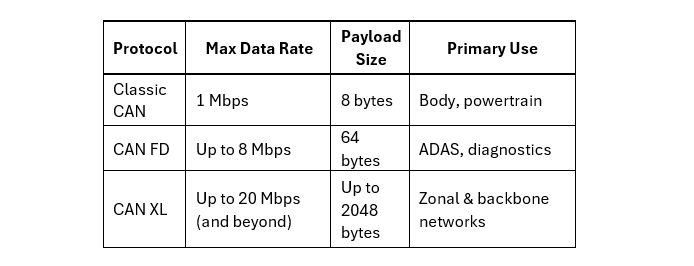

Classical CAN, operating at up to 1 Mbps with an 8-byte payload, remains widely used for body electronics and powertrain control. As vehicle software grew in size and complexity, this limitation became a bottleneck, especially for diagnostics and firmware updates. CAN FD addressed this challenge by increasing payload size and allowing higher data rates during transmission.

CAN XL represents the next phase of evolution, designed to support future zonal and centralized architecture. With payload sizes extending to kilobytes and data rates reaching tens of megabits per second, CAN XL positions itself as a high-performance control and data transport protocol that complements Automotive Ethernet rather than replacing CAN.

The evolution reflects the shift from signal-oriented communication to data-centric and service-oriented architectures.

CAN FD Controller

CAN FD is an enhancement to classical CAN, standardized under ISO 11898-1, that improves throughput while maintaining CAN’s arbitration and error-handling mechanisms. The defining characteristic of CAN FD is its ability to switch bit rates within a single frame. Arbitration occurs at a nominal speed to ensure compatibility and determinism, while the data phase operates at a significantly higher rate to improve efficiency.

A CAN FD controller implements dual bit timing logic, enhanced frame formatting, and stronger CRC mechanisms to support larger payloads of up to 64 bytes. These controllers are typically integrated into automotive microcontrollers and SoCs, providing features such as transmit and receive FIFOs, DMA support, interrupt handling, and fault confinement. From a system perspective, CAN FD controllers strike a balance between performance improvement and backward compatibility, making them ideal for incremental upgrades of existing vehicle networks.

Key Features

- Flexible Data Rate

- Arbitration phase at nominal bit rate

- Data phase up to 8 Mbps

- Larger Payload

- Payload size increased from 8 bytes to 64 bytes

- Improved CRC

- Stronger error detection for larger frames

- Backward Compatibility

- CAN FD nodes coexist with Classical CAN nodes (with restrictions)

CAN FD Controller Architecture

A typical CAN FD controller includes:

- Protocol engine (arbitration, frame formatting)

- Bit timing logic for dual-rate operation

- Error management and fault confinement

- Tx/Rx FIFOs with DMA support

- Interrupt and register interface (often AMBA APB/AHB)

Automotive Applications of CAN FD

CAN FD is already widely deployed in production vehicles and has become the preferred choice for bandwidth-intensive applications that do not justify the cost and complexity of Ethernet. In ADAS systems, CAN FD enables faster and more reliable exchange of control and status information between sensors and processing units. In diagnostics and ECU flashing, the increased payload size significantly reduces programming time, which is critical for OTA update strategies.

Electrified powertrains also benefit from CAN FD, particularly in battery management systems and inverter control, where timely data exchange improves efficiency and safety. Body and comfort systems increasingly use CAN FD to support richer feature sets while maintaining deterministic behavior and low cost.

Key Use Cases

- ADAS and Sensor Communication

- Radar, ultrasonic, and camera metadata transfer

- Faster command and control paths

- Diagnostics and Flash Programming

- Significantly reduced firmware update time

- Essential for OTA-enabled ECUs

- Powertrain and Electrification

- Battery management systems (BMS)

- Inverter and motor control coordination

- Body and Comfort Systems

- Faster response for complex body electronics

CAN XL Controller

CAN XL is designed for the future of automotive networking, where data volumes, software modularity, and centralized control dominate system design. Unlike CAN FD, CAN XL introduces a new frame structure with distinct protocol phases, enabling much higher data rates and payload sizes of up to 2048 bytes.

A CAN XL controller supports a multi-phase communication model that separates arbitration from high-speed data transfer. This design allows CAN XL to retain CAN’s deterministic arbitration while achieving performance closer to Ethernet for selected traffic types. CAN XL is also designed with IP-based communication in mind, enabling efficient transport of service-oriented and software-defined data streams.

Architecturally, CAN XL controllers are more complex than CAN FD controllers. They include enhanced buffering, segmentation and reassembly logic, and tighter integration with high-performance processing subsystems. These capabilities make CAN XL well suited for zonal controllers, backbone communication, and gateway applications in next-generation vehicles.

Key Features:

- High Bandwidth

- Data rates starting at 10–20 Mbps, scalable further

- Very Large Payloads

- Payload size up to 2048 bytes

- Protocol Phases

- Arbitration Phase (CAN-like)

- Control Phase

- Data Phase (XL frames)

- Native IP and Ethernet Coexistence

- Designed to transport IP-based data efficiently

- Future-Ready Security

- Enables MAC-level security and higher-layer protection

CAN XL Controller Architecture

CAN XL controllers typically consist of:

- Multi-phase protocol state machine

- Enhanced buffering and segmentation logic

- Hardware acceleration for frame handling

- Support for gateways and protocol tunneling

- Interfaces to high-performance SoCs and zonal controllers

Automotive Applications of CAN XL

CAN XL targets emerging vehicle architectures built around zonal controllers and centralized compute platforms. In such architectures, CAN XL can serve as a high-bandwidth backbone connecting multiple zones while reducing wiring complexity and ECU count. Its ability to carry large payloads makes it suitable for service-oriented communication models aligned with AUTOSAR Adaptive and modern middleware frameworks.

CAN XL is also well positioned as a gateway technology, aggregating traffic from multiple CAN FD networks and interfacing efficiently with Ethernet backbones. For future ADAS and autonomous driving systems, CAN XL provides a deterministic, high-performance control channel that complements Ethernet-based sensor data streams.

Key Use Cases

- Zonal Architecture Backbones

- High-bandwidth communication between zone controllers

- Reduction of wiring harness complexity

- Service-Oriented Communication

- Transport of service messages and software objects

- Alignment with AUTOSAR Adaptive and SOA concepts

- Gateway Aggregation

- CAN XL as a high-performance gateway between CAN FD and Ethernet

- Future ADAS and Autonomous Systems

- Control and coordination data for Level 3+ autonomy

- Complementary to Automotive Ethernet

Choosing CAN-FD and CAN-XL technologies

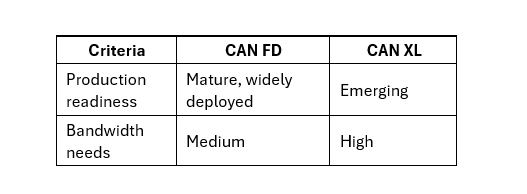

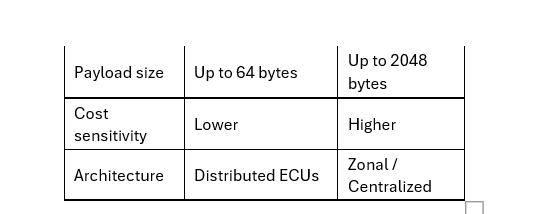

CAN FD and CAN XL are not competing technologies but rather complementary solutions addressing different stages of automotive network evolution. CAN FD is mature, cost-effective, and ideal for today’s distributed ECU architectures. CAN XL, while still emerging, is designed for future vehicles that demand higher bandwidth, larger data transfers, and seamless integration with IP-based communication.

In real-world vehicle designs, classical CAN, CAN FD, CAN XL, and Automotive Ethernet will coexist, each serving a specific role based on performance, cost, and architectural requirements.

In practice, vehicles will use all three—Classic CAN, CAN FD, and CAN XL—alongside Ethernet.

Role of CAN Controllers in SoC and Virtual Platforms

Modern automotive SoCs integrate multiple CAN FD and CAN XL controllers to support complex network topologies. This integration requires careful hardware-software co-design, accurate timing behavior, and robust error handling. To meet aggressive development schedules, automotive OEMs and Tier-1 suppliers increasingly rely on virtual platforms and SystemC/TLM-based models of CAN controllers.

Virtual CAN FD and CAN XL models enable early software development, SIL and HIL validation, and system-level performance analysis long before silicon is available. These virtual environments play a critical role in reducing integration risk and accelerating time to market.

Thius, Modern automotive SoCs integrate multiple CAN FD and CAN XL controllers, requiring:

- Hardware-software co-development

- Accurate timing and error modeling

- Virtual prototypes using TLM/SystemC models

- Early software validation using virtual ECUs

Virtual CAN FD/XL controllers are increasingly used in SIL, HIL, and cloud-based validation flows to accelerate development cycles.

CAN FD and CAN XL controllers are critical enablers of the automotive industry’s transition toward software-defined, data-centric vehicles. While CAN FD addresses immediate bandwidth and efficiency needs, CAN XL prepares the ecosystem for future architectures that demand higher throughput, scalability, and IP-based communication.

Together, they ensure that CAN remains a relevant, robust, and future-proof technology in the evolving automotive landscape.

At LeadSOC Technologies, we actively work on next-generation SoC design, virtual prototyping, protocol modeling, and system-level validation across CAN FD, CAN XL, Automotive Ethernet, and advanced interconnects.

We invite you to subscribe to LeadSOC’s blogs on LinkedIn to stay updated with our latest technical insights, industry perspectives, and practical engineering experiences. To learn more about our capabilities, solutions, and engagement models, please visit www.leadsoc.com.

Let’s engineer the future of automotive systems together.